The energy sector is a dynamic and multifaceted industry essential to powering the world. It encompasses a broad range of activities, including both fossil and renewable energy sources. Each sector presents unique challenges and monitoring needs, driven by the complexities of extracting and harnessing energy from the earth.

Energy Sources and Their Potential

In the ever-evolving energy landscape, a diverse range of sources are essential to meet growing global demands while also addressing sustainability goals. The energy sector is not only responsible for providing power to industries, homes, and transportation but also plays a crucial role in shaping economic and technological progress. To maintain this balance, a mix of traditional and emerging energy sources is necessary. Each type of energy, whether fossil-based or renewable, comes with its own set of benefits, challenges, monitoring needs, and planned maintenance requirements.

As the energy sector adapts to increasing pressures for cleaner, more sustainable practices, new technologies and methodologies are being integrated alongside existing systems.

Effective condition monitoring is key to optimizing performance, ensuring safety, and reducing environmental impact in a cost-effective manner. This ongoing shift highlights the critical role of various energy sources in shaping a future where energy demands can be met responsibly.

Oil & Gas Upstream (O&G)

The O&G sector encompasses the exploration and production of hydrocarbons, meeting the majority of global energy demands while driving economic growth and technological innovation. However, these operations face challenges, particularly in monitoring and managing reservoirs to ensure safe and efficient production.

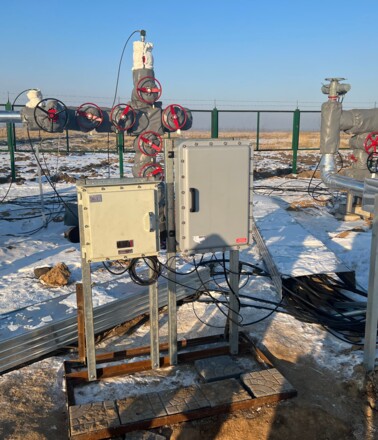

Modern reservoir management relies on real-time, continuous downhole monitoring to optimize performance. Fiber optic sensors can play an important role in this process, providing precise data on temperature and acoustic signals. This enables better decision-making while enhancing the safety and efficiency of extraction operations.

In addition to operational improvements, fiber optic technology helps reduce the environmental footprint of upstream activities. By enabling early detection of issues such as leaks, it prevents hazards and supports sustainable practices. With fiber optics, the industry can enhance hydrocarbon recovery and adopt data-driven strategies to achieve more efficient and environmentally responsible operations.

Carbon Capture & Storage (CCS)

As the world strives to address climate change, Carbon Capture & Storage (CCS) emerges as a vital technology for managing carbon emissions. CCS is key to reducing the carbon footprint of the energy sector, particularly in the ongoing use of fossil fuels. By capturing carbon dioxide emissions from industrial processes and power generation before they reach the atmosphere, CCS mitigates the environmental impact of traditional energy sources.

This technology is essential for balancing the continued reliance on hydrocarbons with the urgent need to combat climate change, making it indispensable in the global transition to a low-carbon future.

During the process of capturing and storing CO₂ underground, fiber optic monitoring enhances the safety and reliability of storage sites. By providing real-time data on CO₂ movement and detecting potential leaks, this technology ensures the integrity and long-term security of carbon storage, safeguarding environmental safety.

Geothermal Monitoring

Geothermal resources stand out as a reliable and sustainable power source. By harnessing the Earth's natural heat, geothermal energy generates electricity with a minimal environmental footprint. It is increasingly recognized as a vital component in diversifying the global energy mix.

Fiber optic technology is instrumental in monitoring temperature gradients and seismic activity within geothermal reservoirs. Its robust design allows it to withstand harsh geothermal environments, making it a durable and reliable solution for continuous monitoring. Additionally, fiber optics provide an environmentally safe solution, ensuring the long-term safety and efficiency of geothermal energy extraction.

Geophysical Monitoring

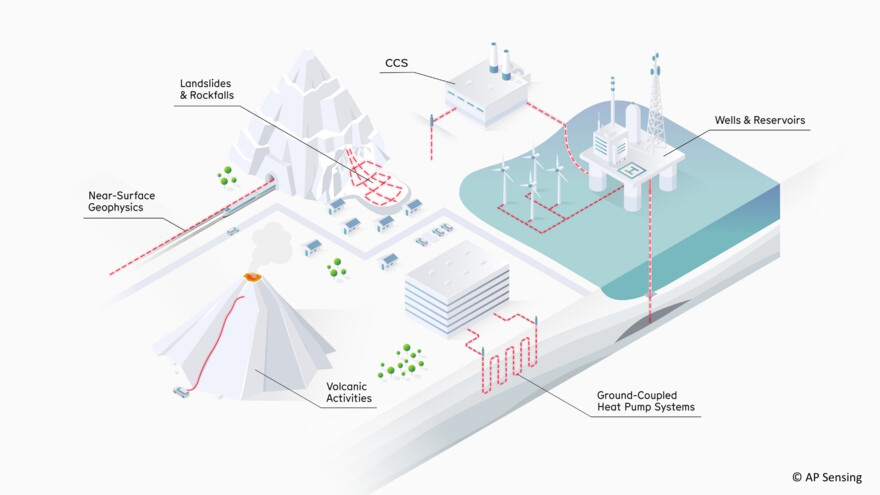

Geophysical monitoring is vital across the energy sector, providing crucial data for decision-making and risk management. In O&G exploration, techniques like seismic imaging identify reserves and assess subsurface conditions, reducing various types of risks. For geothermal energy, it ensures safe heat extraction by mapping subsurface structures and monitoring potential hazards. In CCS, geophysical monitoring tracks stored carbon dioxide to guarantee secure containment.

Additionally, geophysical monitoring allows for precise evaluation of potential near-surface hazards, including ground deformation and emerging underground instabilities. An essential component is the monitoring of seismic events, which greatly enhances our understanding of subsurface processes, helping to safeguard both people and the environment.

Fiber optic sensors offer numerous advantages for geophysical monitoring, such as continuous, high-resolution data collection over long distances without interruption. These sensors provide real-time, reliable insights into subsurface conditions, significantly improving the accuracy of hazard detection and subsurface mapping. Another key benefit is the ability to repurpose existing telecom fibers for geophysical monitoring, maximizing resource utilization.

Monitoring parameters such as temperature, pressure, acoustic signals, deformations, and seismic activity provide critical data that enhance decision-making and operational efficiency. As energy exploration becomes more complex, the need for accurate, real-time data has never been more crucial. Our technology offers precise and continuous monitoring across various energy sectors, such as:

- Landslides & rockfalls

- Near-surface geophysics

- Mining

- Dam infrastructure: leakages & seepages

- Earthquakes

- CO2 pipeline transportation

- Underground injection

- Permanent storage

- Well integrity and well equipment

- Production/injection profiling

- Borehole seismic

- Hydraulic fracturing

- Enhanced oil recovery (EOR) projects

- Subsea umbilicals and risers

- Geothermal power plants

- Surface/borehole DFOS seismic surveys

- Production wells

- Injection wells

- Gound-coupled heat pump systems

- Volcanic activities

Specific Challenges and Opportunities

The energy sector faces numerous challenges, including the need for reliable, real-time monitoring in harsh environments, the integration of renewable energy sources, and the reduction of carbon emissions. Additionally, conventional tools often struggle with long-term stability and accuracy, which can lead to inefficiencies and increased operational risks. Managing these challenges requires advanced technology and innovative solutions.

Current Trends in Energy Exploration & Monitoring

- Decarbonization

- Cost-effective solutions

- Mitigation of risks associated with traditional monitoring tools

- Sustainable practices

- Adoption of renewable energy sources

- Enhacement of the overall operational efficiency and safety

- Proactive maintenance

Fiber optic sensing technologies are increasingly favored for their ability to provide continuous, real-time data with high precision, supporting these trends.

AP Sensing's Solutions and Their Advantages

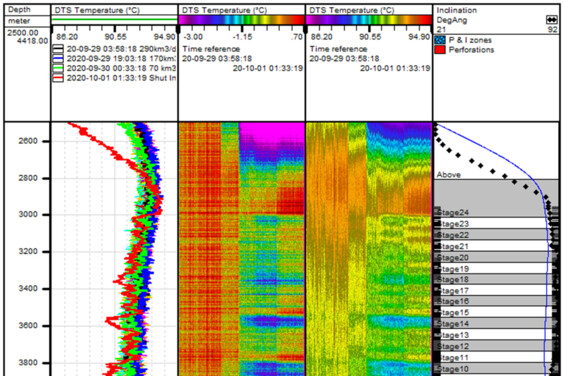

Distributed Temperature Sensing (DTS)

AP Sensing’s DTS is based on the proven Raman optical time domain reflectometry technology (R-OTDR). AP Sensing uses its patented code correlation OTDR (CC-OTDR) that allows utilization of low optical power. It eliminates any problems with laser degradation and enables worry-free, long-term measurement stability.

AP Sensing’s DTS technology plays a critical role in various energy applications by providing real-time, continuous temperature data along large areas:

- In O&G upstream, it helps optimize well performance, detect anomalies, and ensure integrity.

- For geothermal energy, DTS monitors temperature gradients to ensure efficient heat extraction and operational safety.

- In Carbon Capture & Storage (CCS), it provides input in CO₂ movement tracking, ensuring site integrity and detecting leaks.

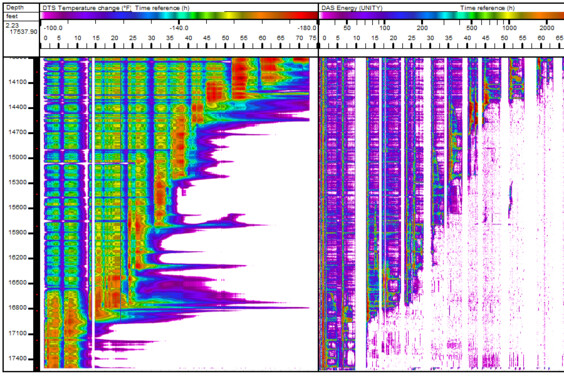

Distributed Acoustic Sensing (DAS)

The AP Sensing’s phase-based DAS system measures the acoustic vibrations on the fiber based on the principles of coherent optical time domain reflectometry (C-OTDR). The revolutionary 2P Squared technology of DAS provides a true linear measurement of dynamic fiber length changes caused by strain from acoustic/vibration signals or temperature fluctuations.

- AP Sensing’s DAS enhances O&G upstream operations by detecting acoustic signals related to flow dynamics, leaks, which aids in optimizing well performance and real-time issue identification.

- In geothermal energy monitoring applications, DAS records acoustic signals to track subsurface activities, ensuring efficient heat extraction and reservoir monitoring.

- In geophysical applications, DAS provides high-resolution, continuous data for subsurface imaging, seismic monitoring, and resource exploration.

- In CCS, DAS tracks acoustic signals to monitor CO₂ injection and migration, ensuring site integrity and detecting potential leaks.

Distributed Temperature & Strain Sensing (DTSS)

AP Sensing’s DTSS is based on the Brillouin optical time domain reflectometry (BOTDR) technology. BOTDR operates with a large optical budget on a single-ended fiber, being less affected by changes in fiber attenuation. BOTDR enables extensive and accurate measurements of both temperature and strain within the sensing range.

AP Sensing’s DTSS provides critical insights across various sectors by measuring strain and deformation along the length of fiber optic cables:

- In O&G upstream, DTSS helps monitor wellbore stability and detect deformation or shifts that could impact well integrity.

- For geothermal energy, it tracks strain in subsurface structures to ensure efficient heat extraction and stability of geothermal reservoirs.

- In geophysical monitoring, DTSS detects ground deformation by measuring strain along fiber optic cables.

- In CCS, it detects strain changes in storage sites to monitor CO₂ movement and ensure site integrity, helping to identify potential issues early.

Our Innovative Software Solutions

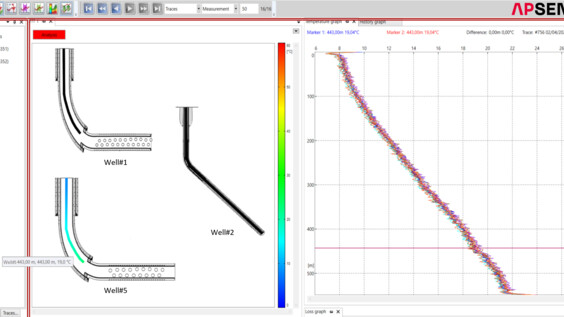

SmartVision

AP Sensing's SmartVision suite offers a comprehensive view of your asset at a glance, controlled by an intuitive graphical user interface (GUI). It seamlessly integrates various technologies, including DAS, DTS, DTSS and other sensors, into a single platform. In emergency situations, alarms are displayed on the screen, promptly informing operators about the location of critical incidents, while temperature graphics and hotspot tables are readily accessible.

PLATO-DTS

PLATO-DTS is designed to visualize and interpret DTS data from any well, enabling the extraction of production and injection profiles. Utilizing an enthalpy balance model, PLATO-DTS accounts for heat transfer through both conduction and convection. The model naturally predicts temperature changes due to frictional heating, Joule-Thompson cooling, skin effects, and phase changes. With features that optimize DTS data from visualization to permanent monitoring, PLATO-DTS has become the industry standard for temperature modeling.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.