Distributed Temperature and Distributed Strain Sensing systems (DTSS) measure temperature or strain along fiber optic cables for comprehensive asset monitoring. This technology provides precise temperature data for temperature monitoring or detects mechanical strain, enabling the identification of stress and potential deformations. By analyzing light interactions within the fiber optic cables, DTSS systems deliver real-time data, supporting preventive maintenance and corrective actions for critical assets such as power cables, pipelines, and infrastructure (i.e. bridges, dams and other buildings) , ensuring thermal stability and mechanical integrity.

How DTSS Works

Distributed Temperature & Strain Sensing (DTSS) utilizes standard optical fibers, often spanning dozens of kilometers, to monitor temperature or mechanical strain across an asset. These systems provides a spatially well-resolved profile, enabling real-time measurement of temperature or strain distributions with high accuracy, making it ideal for long infrastructure such as pipelines, power cables, and structural assets. A combination of temperature and strain sensing ensures comprehensive asset health monitoring, offering insights into both thermal and mechanical conditions with a resolution down to one meter along the fiber.

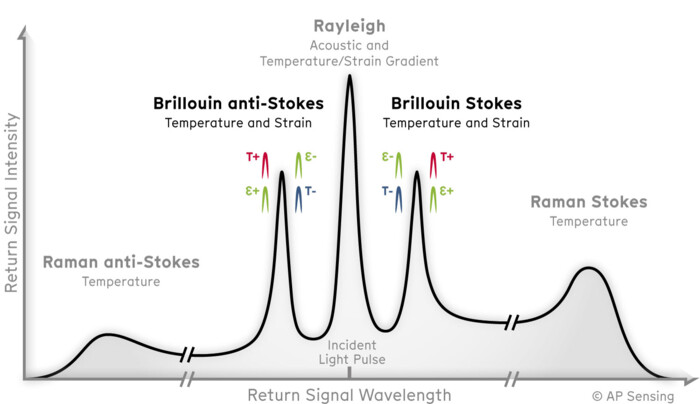

DTSS technology is based on Brillouin optical scattering, which responds to both, temperature and strain along the optical fiber. When a laser pulse is launched into the fiber, light is scattered back due to the interaction with the fiber material. The optical properties of the backscatter, such as frequency and amplitude, vary depending on the temperature and strain applied to the fiber. This data is continuously analyzed. The system uses optical time domain reflectometry (OTDR) to precisely locate where changes are happening by measuring the time delay of the returning signal, much like radar.

Brillouin Technology for Temperature & Strain Monitoring

In Brillouin-based DTSS systems, the backscatter signal properties depend on both, temperature and strain changes, making it possible to monitor both conditions. Analyzing temperature and strain effects along optical fibers enables early detection of potential risks, such as overheating, stress fractures, or mechanical deformations, ensuring the safety and longevity of critical infrastructure. This provides a holistic view of asset health, allowing for timely interventions and minimizing the risk of catastrophic failures.

Benefits & Advantages of Distributed Temperature & Strain Sensing

Distributed Temperature & Strain Sensing (DTSS) technology offers advanced monitoring capabilities by tracking temperature or mechanical strain along an optical cable , ensuring the reliability and safety of critical infrastructure assets.

Continuous Temperature & Strain Profile Measurement

DTSS systems provide continuous, real-time monitoring of thermal or strain conditions, allowing precise localization of anomalies such as hotspots or mechanical stress. Covering dozens of kilometers per measurement unit, these systems ensure comprehensive asset monitoring. For applications like power cables or pipelines, this capability allows for the early detection of temperature abnormalities or stress points, preventing costly damage or failure. Additionally, continuous thermal or strain data enables precise management of operations such as cool-down phases or stress relief in critical infrastructure.

Maximum Reliability Under Harsh Conditions

DTSS systems are designed to function reliably in extreme industrial environments, including those with high heat, dust, dirt, or corrosive elements. The optical fibers used are non-corrosive making them ideal for harsh environments. Depending on the fiber design and coating, DTSS technology can monitor a wide temperature range, while withstanding harsh mechanical stresses.

Immunity to Electromagnetic Interference

One outstanding advantage of DTSS systems is their immunity to electromagnetic interference (EMI), which is crucial for environments with high levels of electrical noise, such as power substations or industrial plants. As the sensors are optical, they are not disturbed by EMI or radio frequency interference (RFI), ensuring accurate and uninterrupted data transmission even in challenging electromagnetic environments. This makes DTSS systems a reliable solution for continuous monitoring in such conditions, providing undisturbed readings of both temperature and strain.

High Sensitivity and Accuracy

The sensitivity of DTSS systems ensures that even minor temperature or strain changes can be detected in real-time. This high level of accuracy is essential for applications where small variations can indicate critical changes, such as in pipeline or structural health monitoring. By detecting these changes early, DTSS technology enables predictive maintenance, improving the lifespan and safety of monitored assets.

Cost-Effectiveness and Low Maintenance Requirements

Cost-effectiveness and low maintenance requirements

DTSS systems offer significant cost savings compared to traditional sensor-based systems. Using a single passive optical fiber to monitor long distances reduces the need for multiple sensors and associated installation costs. The distributed nature of DTSS means that any point along the fiber is monitored equally, ensuring complete coverage without gaps. Furthermore, the low maintenance requirements of optical fibers contribute to long-term operational efficiency and cost-effectiveness, making DTSS a preferred solution for industries looking to reduce both downtime and maintenance expenses.

By leveraging these benefits, Distributed Temperature & Strain Sensing provides industries with a robust, reliable, and cost-effective monitoring solution for maintaining the integrity of critical infrastructure under thermal or mechanical stress.

Use Cases of DTSS Systems

Distributed Temperature & Strain Sensing (DTSS) systems are critical for real-time monitoring of thermal or mechanical stress in various infrastructure applications. Leveraging Brillouin-OTDR technology, DTSS systems provide comprehensive, high-precision data, ensuring asset safety, longevity and performance.

Key applications include:

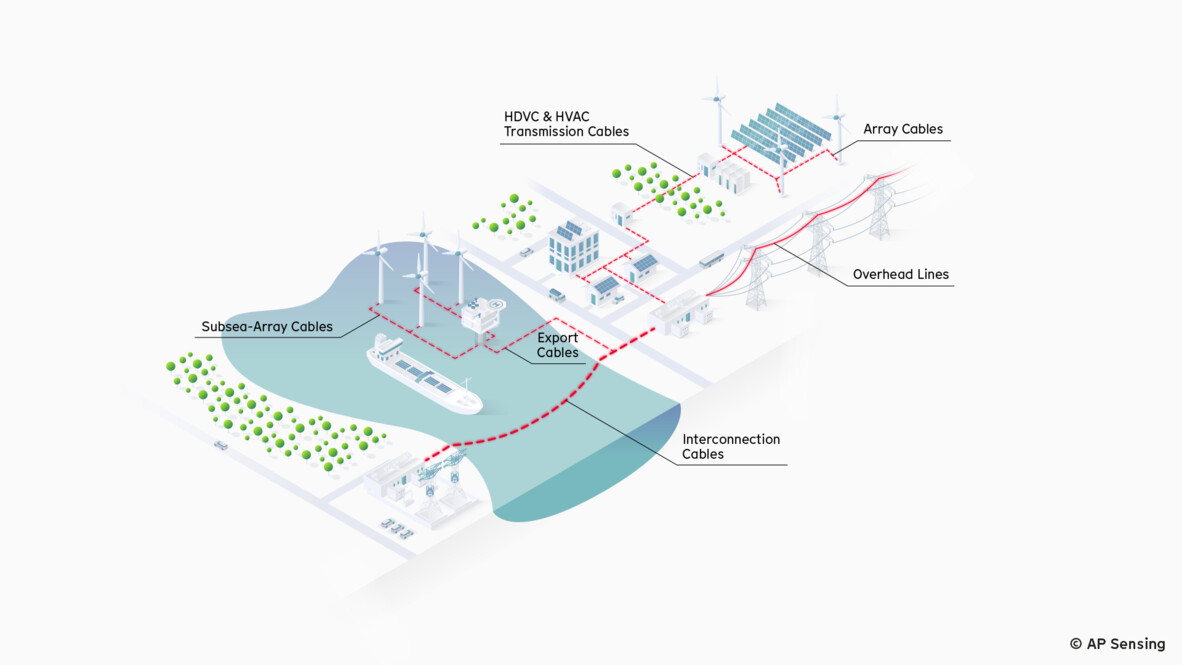

- Power Cable Monitoring:

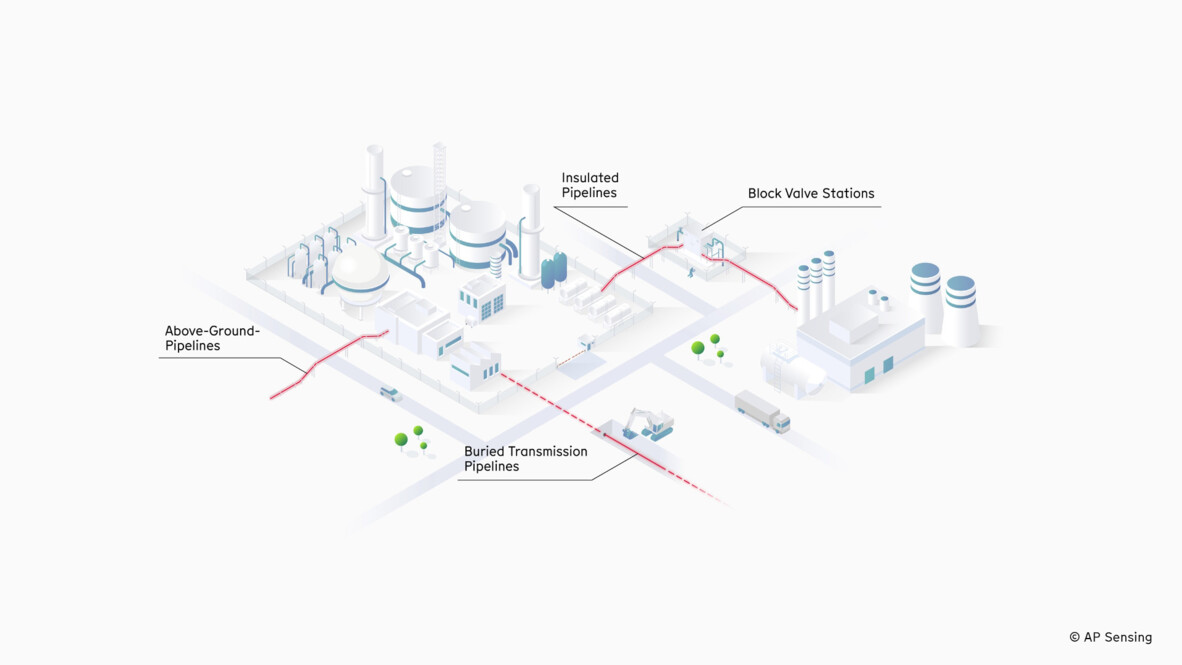

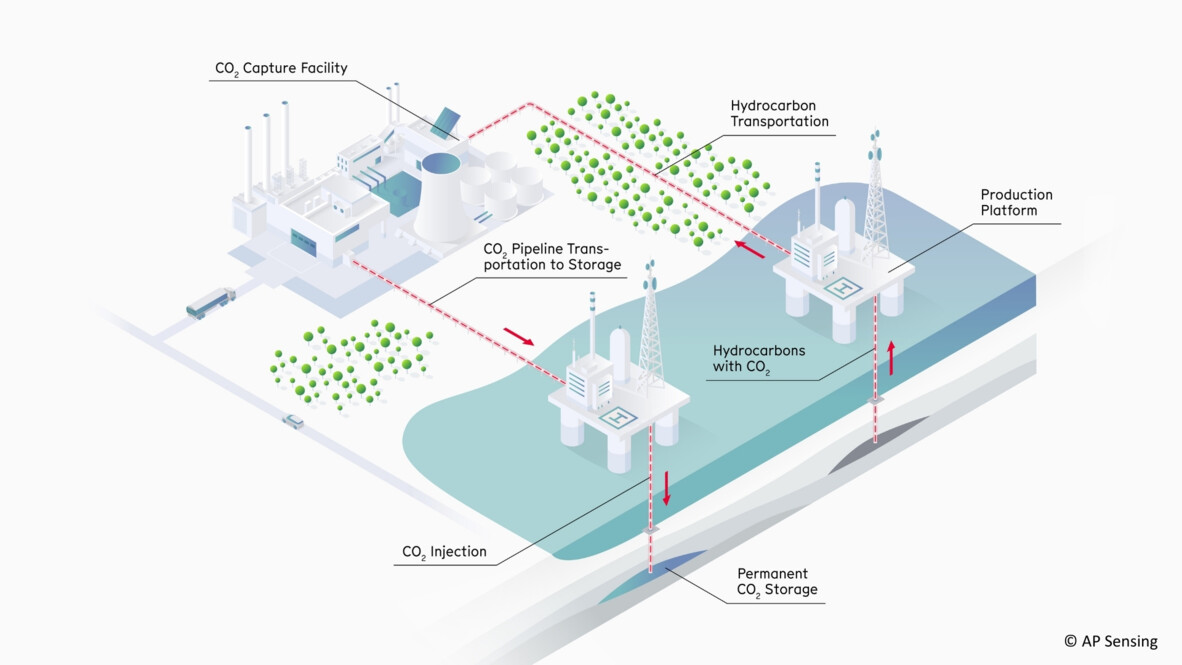

DTSS systems detect overheating and mechanical strain in underground or overhead power cables, preventing damage and ensuring reliability. - Pipeline Monitoring:

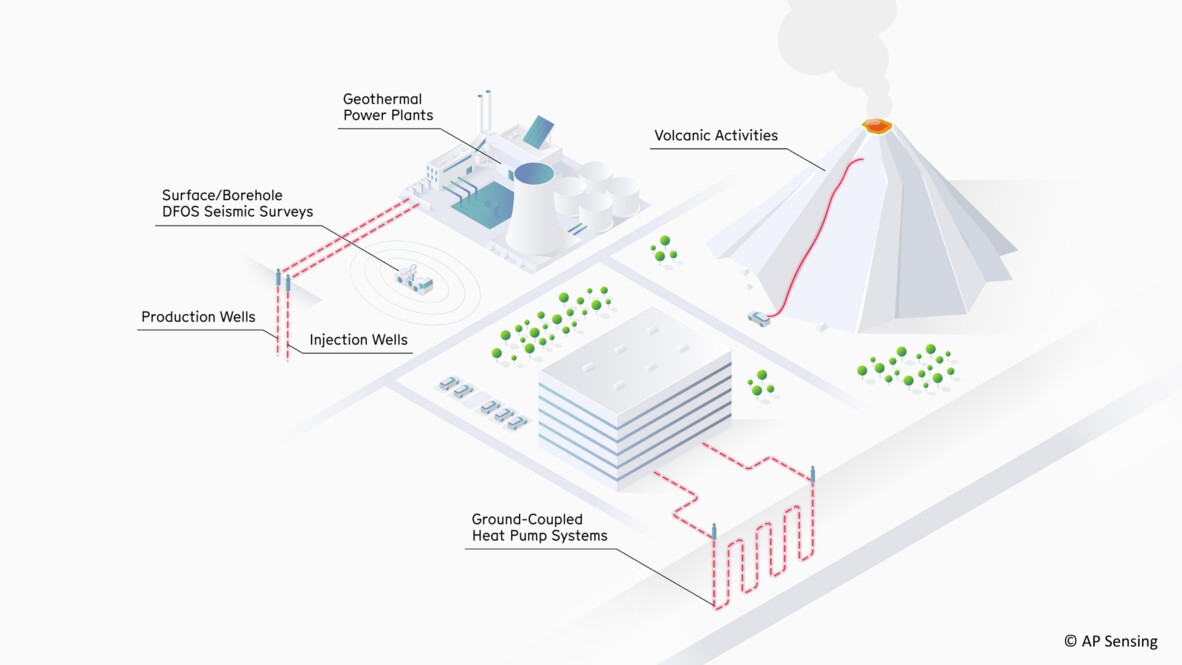

They identify temperature anomalies and mechanical strain along pipelines, enabling early detection of leaks or structural issues. - Geothermal Monitoring:

DTSS systems monitor thermal and mechanical changes in geothermal wells, helping manage pressure and temperature fluctuations for safe energy extraction. - Dike & Dam Monitoring:

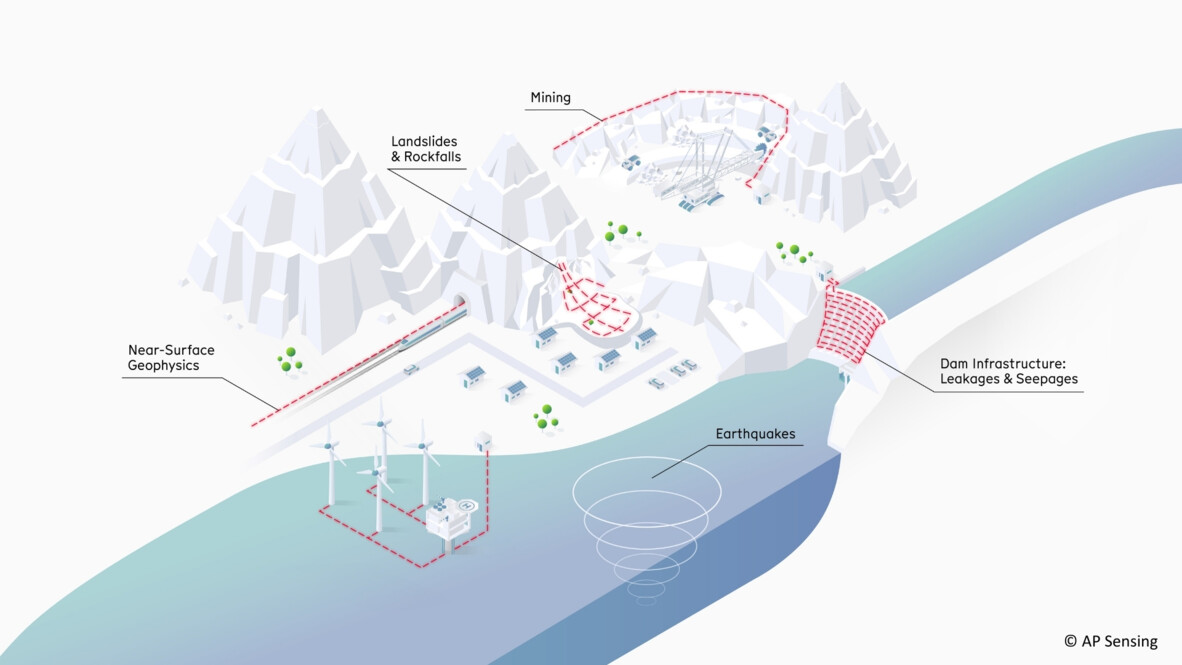

These systems detect strain and temperature shifts in dam structures, offering early warnings of potential failures, detecting leakages and seepage. - Landslide Monitoring:

By detecting ground movement and stress variations, DTSS systems provide critical data for preventing landslides. - Structural Health Monitoring:

DTSS systems track strain and temperature in bridges, tunnels, and buildings, ensuring long-term structural integrity. - Well & Reservoir Monitoring:

In oil, gas, and water reservoirs, DTSS systems monitor thermal conditions and mechanical stress for optimized resource extraction. - Railway Monitoring:

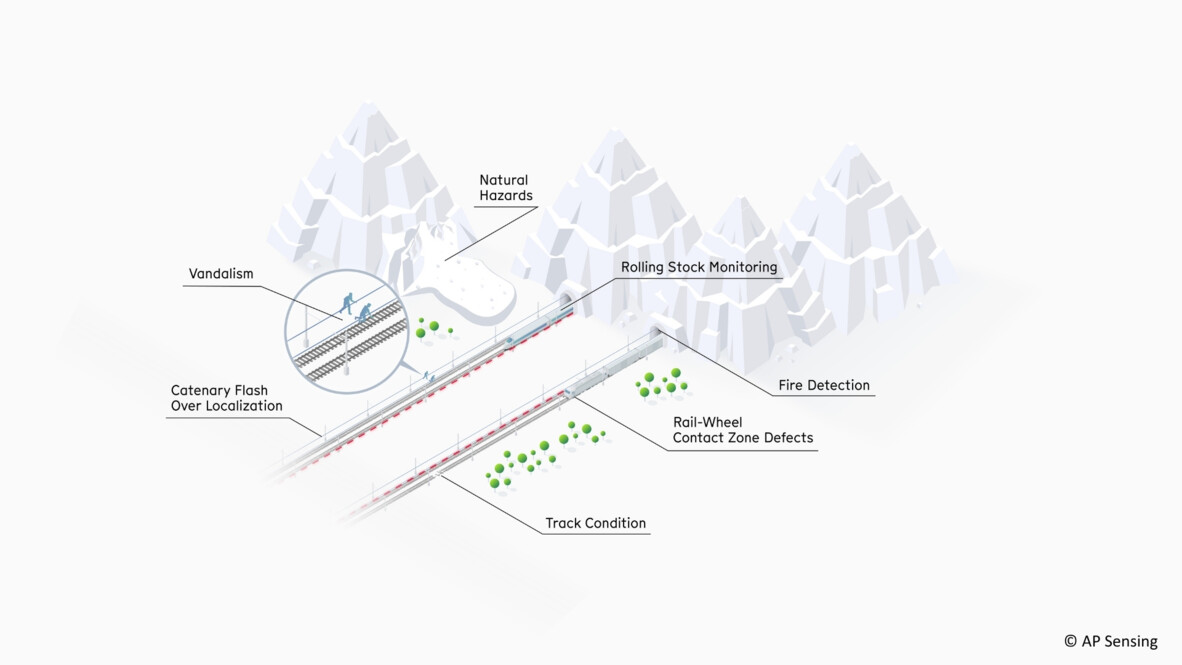

DTSS systems identify thermal expansion and strain in rail tracks, maintaining track integrity and preventing derailments.

These applications ensure continuous, reliable monitoring of infrastructure, contributing to enhanced safety and operational efficiency.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements.

Key Takeaways

Distributed Temperature & Strain Sensing (DTSS) systems offer a comprehensive approach to asset monitoring by measuring temperature or mechanical strain over large distances. Utilizing Brillouin-OTDR technology, DTSS provides real-time data with high spatial resolution and measurement accuracy, enabling early detection of thermal anomalies or structural stress.

This makes DTSS suitable for a wide range of industries, including power cable, pipeline, and infrastructure monitoring. It enhances operational safety, prolongs asset life, and helps prevent failures, offering a reliable solution for maintaining the integrity of critical infrastructure.

Frequently Asked Questions (FAQs)

This FAQ section shares practical, vendor-neutral insights to support engineers, operators, and decision-makers working with DFOS.

It is supported by Dr. Gregor Cedilnik, Principal Research Scientist at AP Sensing and a leading expert in distributed fiber optic sensing technologies. With decades of experience in fiber optics, photonics, and DFOS system design, he has authored numerous technical publications and patents and helped shape several of AP Sensing’s core platforms.

What is Distributed Temperature & Strain Sensing (DTSS)?

DTSS uses an optical fiber as used in telecommunication as a continuous sensor to measure temperature and mechanical strain along many kilometers. It provides gapless profiles and precise localization of thermal changes and structural deformation.

How does DTSS work - in simple terms?

Short optical pulses are launched into the fiber. A small fraction of the light is scattered back through the Brillouin interaction with the glass. The Brillouin frequency shift and backscatter amplitude vary as a function of temperature and strain. By analyzing this frequency shift, the amplitude, or the combination of both, the system determines the temperature and strain distribution along the fiber. The time delay between launching the pulse and receiving the respective Brillouin backscatter (time-of-flight) is used to calculate the sensing location along the fiber.

How are temperature and strain separated?

Brillouin frequency shift and amplitude depend on both strain and temperature. DTSS can employ different approaches to separate the temperature and strain information.

One approach uses a sensing fiber that is installed strain-free within the cable, e.g. by FIMT (fiber in metal tube). This way the Brillouin signal on that fiber represents only the temperature distribution.

Another approach is an instrument design and processing technique to decouple temperature and strain from multiple measurement quantities, e.g. from both, the frequency shift and amplitude information which have different sensitivities for strain and temperature, allowing to derive how much the Brillouin signal is impacted by strain and how much by temperature.

What distances and spatial resolution are typical for DTSS?

DTSS typically covers tens of kilometers per channel with meter-class spatial resolution. Shorter links and optimized configurations can achieve finer resolution; very long links may require coarser spacing or longer averaging to maintain SNR.

Which fiber types are used for DTSS?

Standard single-mode fiber (SMF) is preferred for long-range, low-loss performance. Bend-insensitive SMF helps in tight routing. Cable construction (e.g., armored, loose-tube, bonded) should match the environment and, in case of strain measurement, an appropriate strain transfer to the fiber.

How fast are DTSS measurements updated?

Update rates are usually in the order of seconds to minutes, depending on sensor length, required spatial resolution and temperature accuracy, and whether both temperature and strain are being solved simultaneously. Faster updates are possible on shorter sensors because of lower signal losses and higher possible interrogator pulse rate.

What drives Distributed Temperature & Strain Sensing (DTSS) accuracy and stability?

Key factors include the instrument's signal-to-noise ratio (SNR), fiber attenuation and the quality of splices and connectors, strain transfer from the asset to the fiber (bonded vs. loosely coupled cable installation), thermal coupling to the asset, calibration method, and instrument settings (frequency sweep range and resolution, spatial resolution setting, measurement time setting).

Where is DTSS used?

Common uses include pipelines (ground movement, settlement, geohazards), power cables and ducts (thermal loading and mechanical strain), geotechnical/structural health (tunnels, bridges, embankments, dams), rail and road corridors, and subsea or buried infrastructure.

How is the Distributed Temperature & Strain Sensing (DTSS) sensing cable installed for strain vs. temperature?

For strain sensing, fibers are typically bonded or mechanically coupled to the structure/soil to transfer deformation. For temperature emphasis, fibers may be installed to maximize thermal contact while minimizing unintended strain pickup. Mixed objectives use hybrid layouts.