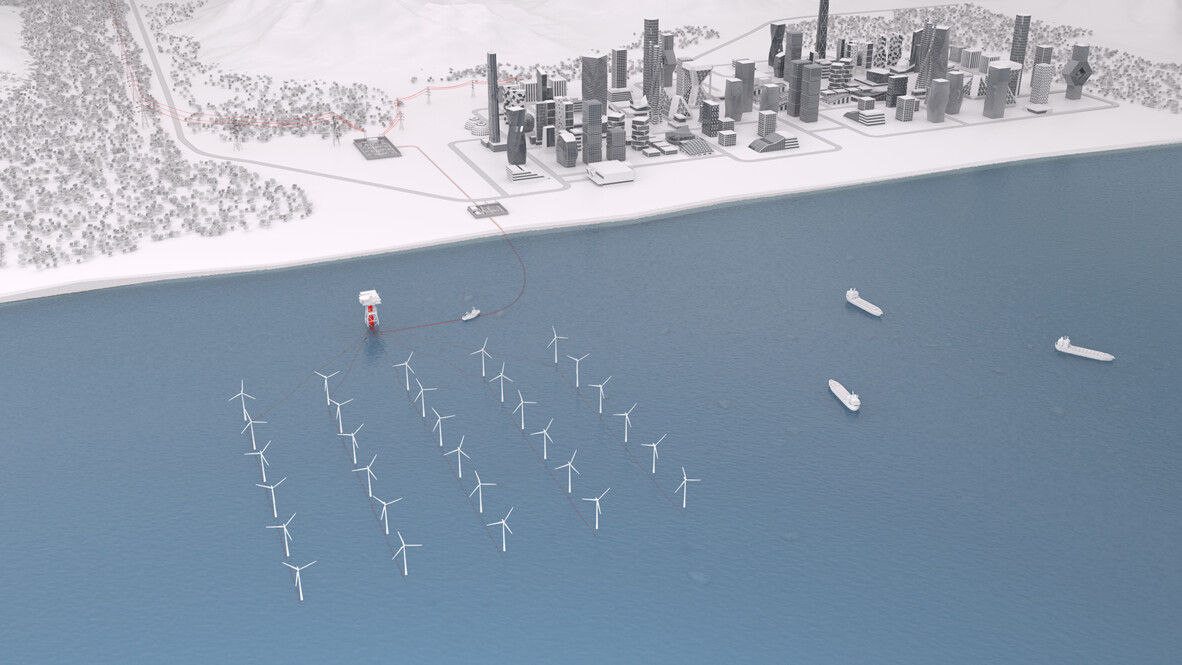

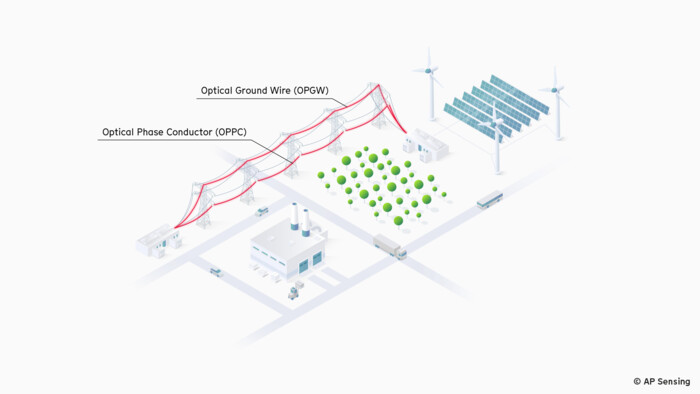

Overhead power lines (OHL) play a crucial role in the transmission of electrical energy, forming the backbone of essential infrastructure networks. Overhead Lines with Fiber Optical Groundwires (OPGW) have become a key component in these networks, supporting reliable communication and power transmission. These systems provide a cost-effective and efficient solution, as no civil works are required, and the established rights of way help minimize both costs and setup time.

In an increasingly connected world, modern overhead line monitoring ensures uninterrupted service by enabling real-time fault detection, condition monitoring, capacity optimization and asset protection. Advanced technologies, such as predictive analytics and real-time data analysis, help utilities operators maintaining reliable, efficient networks while reducing operational costs and improving response times to potential issues. Distributed Fiber Optic Sensing (DFOS) is an ideal solution for monitoring these critical infrastructures, offering precise, real-time insights to ensure performance and safety.

Enhanced Monitoring in Overhead Lines

Overhead power lines are critical to modern electricity infrastructure, serving as the backbone that delivers power from transformer stations to cities and essential services. However, these lines are constantly exposed to environmental threats, including thunderstorms, storms, and other natural hazards, which can disrupt service and cause significant damage. Reliable monitoring of OHL is essential to maintaining an uninterrupted power supply. In days of increasing power demands driven by renewable energy, e-mobility and digitalization, grid stability as well as grid capacity becomes paramount for the development of modern industries and societies.

Technologies like distributed fiber optic sensing significantly contribute to OHL monitoring by allowing continuous, real-time observation along the entire length of the line. With just a single fiber optic telecommunication cable, already commonly deployed along OHL, operators can monitor the entire network, spanning several kilometers, with ease. This capability provides early fault detection, valuable data online conditions and real-time capacity information and hence improves the overall efficiency, enabling measures that reduce downtimes and enhancing overall system stability. Implementing predictive maintenance helps prevent unplanned downtime by addressing potential equipment failures before they occur. Optimizing resource use and improving response times to outages helps utilities increase customer satisfaction and overall grid reliability.

AP Sensing’s Solution for Monitoring OHL

AP Sensing’s advanced monitoring solutions effectively address these challenges to enable predictive asset management and a flexible, efficient operation of an OHL.

AP Sensing’s Distributed Acoustic Sensing technology utilizes a single dark fiber in the OPGW to measure vibrations along the line with highest sensitivity. These vibrations are converted into valuable information, providing deeper insights into the nature and location of events such as:

- Short circuits

- Flashovers

- Icing

- Galloping

- Wire tension

- Lightning strike

- Third Party Intrusions

Vibration information can be used to precisely calculate spatially distributed wind conditions in real time, making DLR (Dynamic Line Rating) results more accurate and cost-effective.

AP Sensing’s Distributed Temperature Technology (DTS) directly measures the temperature of the conductor wire (OPPC/HTLS) up to 100km length per instrument. Direct measurements of temperature offers a straightforward, assumption-free calculation of line capacities and sagging.

Technologies Used for Monitoring OHL

Distributed Temperature Sensing (DTS)

Distributed Temperature Sensing (DTS) is crucial in cable condition monitoring. DTS provides real-time insights into cable performance by identifying hotspots, cold spots, and thermal bottlenecks that could affect efficiency and safety.

One of its key features is the ability to detect even the smallest anomalies from normal thermal behavior through Machine Learning Transient Alarm (MLTA) . This early detection of abnormal conditions allows for timely intervention, optimizing performance and preventing potential failures, ensuring the long-term reliability and safety of the cable network.

Distributed Acoustic Sensing (DAS)

Distributed Acoustic Sensing (DAS) technology is used to monitor overhead power lines by detecting vibrations and acoustic signals that indicate potential risks or faults. DAS provides precise fault location and can identify issues early, helping to prevent damage and maintain reliable operation of the power network.

For overhead lines (OHL), DAS technology can detect snow accumulation on the lines, monitoring the additional load it causes. This allows operators to address the increased strain on the lines before it leads to faults or failures, enhancing the safety and reliability of the system in adverse weather conditions.

Expanding Our Monitoring Solutions

SmartVision Software

SmartVision seamlessly integrates a wide array of DAS, DTS, CCTV, and other sensors within a single platform. Circuit layouts are visually mapped and color-coded, displaying cable temperatures and real-time changes in acoustic energy. Temperature graphs and hotspot tables are easily accessible, and cable route sections can be individually configured with flexible alarm levels and types. Key points of interest such as cable joints, horizontal drillings, and manholes can be analyzed with trend history, with access to historical data always available.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.