Project Overview

In 2020 a major American tech company began looking for a new method of bus duct temperature monitoring for its hyperscale facilities globally, specifically for a continuous monitoring solution for the entire length of high ampacity bus ducts that emerge from UPS rooms. In this case study we describe one project for a UK facility designed and built to operate as a modern hyperscale data center. One challenge of this facility is that the bus duct infrastructure spans across two levels of the building, crossing nearly thirty separate rooms at a typical height of three meters above floor level.

Solution

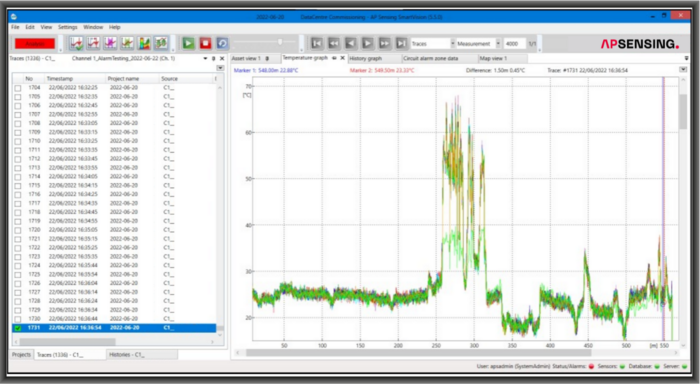

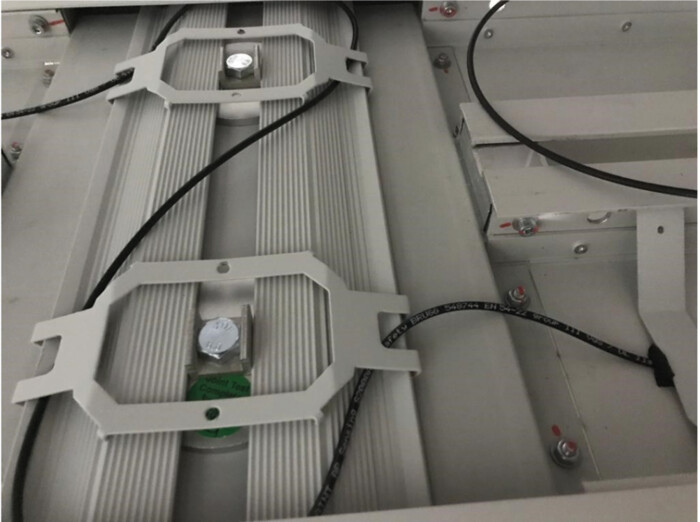

AP Sensing collaborated with a local partner for the deployment of one fiber optic Distributed Temperature Sensing (DTS) unit with four channels; each channel monitors up to approximately four kilometers. Due to physical space constraints, the DTS unit is wall mounted and fitted within an electrical room. The fiber optic sensor cable was fitted along the 1600A and 3200A ampacity bus ducts, including at all joint areas, using custom cable clips. Joint temperature monitoring is particularly important for high ampacity bus ducts. Our DTS solution is configured for Modbus TCP/IP communication and achieved seamless integration to the end client’s operation center. At this facility, an AP Sensing project engineer configured over 100 alarms and over 100 temperature values, enabling the easy visualization of bus duct temperatures and the pinpointing to the exact hotspot for further investigation in the case of an alarm.

Results

After commissioning our DTS solution, the entire bus duct infrastructure was stress tested, meaning the electrical load on the bus duct was increased in a controlled manner. These tests were observed in real time by the end client’s Operation Center and the system registered a maximum temperature value on the entire bus duct infrastructure that was still lower that the limits set by the manufacturer’s certification (IEC 61439-6 Temperature-Rise).

Benefits

Continuous, real-time bus duct monitoring enables early detection of hotspots or other potential issues, enabling proactive maintenance, reduced downtime, and planning of server rack relocation. DTS improves overall facility safety by reducing electrical failures or fires associated with bus duct malfunctions, and reduces maintenance costs by eliminating manual monitoring services and allowing for targeted repairs or replacements rather than a reactive intervention after a failure occurs. With real-time, remote data, facility managers can access data from any location, facilitating rapid decision making and troubleshooting.

Lastly, access to large amounts of monitoring data over time enables operators to identify trends, optimize operations, and predict future maintenance needs. It is typical to use thermography services to periodically inspect bus duct infrastructure. However, manual thermography services require physical access and use a handheld instrument that may capture inconsistent temperature measurements. AP Sensing’s Distributed Temperature Sensing (DTS) solution alleviates these challenges in addition to providing continuous, 24/7 temperature monitoring and assurance of bus duct health throughout the lifetime of a data center.

Conclusion

The end client was very satisfied with the DTS solution implemented and the results of the stress tests. Fiber optic DTS allows for 24/7 bus duct monitoring, early detection of hotspots or potential issues, and eliminates the need for costly traditional thermography services.