Project Overview

Minera Los Pelambres, one of the largest copper mines in Chile, required a real-time monitoring solution for their high-temperature rollers, which are critical components of their conveyor belt systems that transport copper ore. These idlers, which can overheat due to constant friction and heavy loads, pose significant risks of fire and mechanical failure if not properly monitored.

Located in the Región de Coquimbo of Chile near the Andes Mountains, the mine produces over 350,000 metric tons of copper annually, along with molybdenum and gold as by-products. As a key player in global copper production, Minera Los Pelambres faces significant infrastructure challenges, particularly with maintaining and monitoring its extensive conveyor belt systems that operate under harsh environmental conditions.

To address these challenges, Minera Los Pelambres sought a solution that could provide continuous, 24/7 monitoring without the need for personnel to manually inspect high-risk areas.

Solution

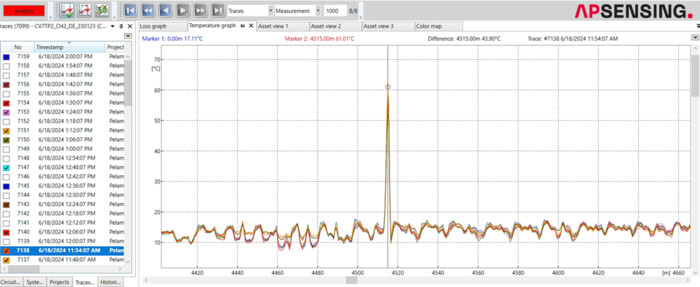

AP Sensing deployed a Distributed Temperature Sensing (DTS) system with two channels to provide continuous, real-time monitoring of the high-temperature rollers. The system was configured with 13,400 meters of multimode fiber optics, installed in a closed-loop setup providing sufficient redundancy.

The DTS is configured for two parallel, independent measurements: One for temperature monitoring along the idlers and one with settings according to UL 521 for fire detection.

One channel is responsible for actively monitoring temperature variations along the conveyor belt, detecting hot rollers i.e. thermal anomalies that could indicate potential overheating or failure.

The other channel is acting as a fiber optic lLnear Heat Detector (LHD) to detect fires following UL, and EN (VdS) standards.

This setup allows Minera Los Pelambres to ensure full visibility of the thermal conditions across their conveyor belt system, reducing the need for manual inspections and improving operational safety and efficiency.

Benefits

24/7 automated monitoring: The system operates continuously, detecting thermal anomalies without requiring personnel to enter hazardous areas.

Safety improvements: The DTS system

reduces the risk of fires and operational downtime.

Cost savings: By preventing unexpected shutdowns, fires, and unplanned component replacements, the DTS system

helps to reduce operational costs and prolong the lifespan of critical assets.

Predictive maintenance: The DTS provides real-time data that is used to predict potential failures before they occur, allowing for proactive maintenance and avoiding downtime.

Environmental benefits: By preventing fire and equipment failures, the system reduces the environmental impact of unplanned shutdowns.

Conclusion

Minera Los Pelambres is fully satisfied with the DTS solution

provided by AP Sensing. The system is now used daily as a predictive monitoring tool, providing regular reports on abnormal conditions and significantly improving operational safety and efficiency.

The next steps include integrating monitoring screens in the control rooms to allow for real-time visualization of the thermal conditions along the conveyor belts. Additionally, the monitoring setup used on one conveyor belt will be replicated across the other belts, ensuring consistent and accurate thermal monitoring throughout the entire system.

With AP Sensing’s innovative fiber optic sensing technology, Minera Los Pelambres has gained full visibility into the thermal conditions of their critical infrastructure, ensuring a safer, more reliable, and cost-effective operation.