Project Overview

The transportation of sulfur via pipelines requires the use of heated pipelines so that the sulfur remains in its liquid form. Typically, the skin effect heating system is used and managed by a heat tracing system to maintain and protect the pipelines, vessels, and instrumentation at pre-defined temperatures. AP Sensing’s fiber optic-based Distributed Temperature Sensing (DTS) system provides insight into temperature profiles along the entire length of the pipeline.

The Habshan region is located in the southwestern United Arab Emirates. Two sulfur transport pipelines with a total length of 76 km use a heat management system to ensure safe and reliable temperatures along the route. Although pipeline transportation is more cost-effective than road or rail—and the cost-effectiveness increases with the pipeline length—the pipeline and heat management systems have their own unique challenges.

Solution

Working together with our global partner Pentair Thermal Management, AP Sensing’s DTS solution was selected to monitor the pipeline temperature with 1 °C temperature and 1 m spatial resolution. AP Sensing was selected due to our pipeline expertise, project management capabilities, design proposals and the quality and reliability of our DTS systems. Additionally AP Sensing‘s design and instrument features deal with potential issues such as higher optical loss on the fibers without impacting the overall system performance and accuracy.

A total of five DTS devices were installed, each with four channels. A dual-ended measurement setup was employed, taking advantage of the auto-calibration functionality. Together with our expert partners, AP Sensing has defined a special sensor cable that can handle rough installation demands and keeps the optical loss of the fiber at an acceptable level during heat up and cool down cycles. This required a very specific fiber over length (FOL) for the 250 °C rated sensor cable. In addition, the design of the pull-in ducts, pull-boxes and other deployment aspects had to be taken into account.

SmartVision

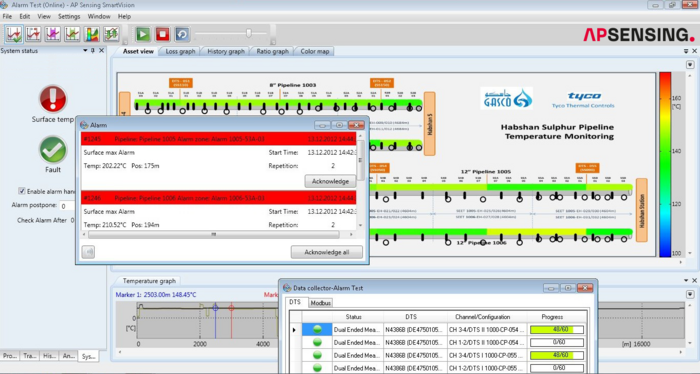

The pipeline operators have the complete overview of the entire length of the pipeline in the remote control room, located several kilometers away from the pipeline. AP Sensing’s asset visualization software SmartVision provides multi-user and multi-DTS device capabilities and data measurement storage. A clear graphical user interface shows the operators color-coded sensor cable routes, indicates the temperature conditions along the lines, and issues alarms if any of the predefined conditions for any zone are exceeded. A Modbus protocol running over TCP/IP was used to smoothly integrate into the onsite IT infrastructure.

Conclusion

AP Sensing’s experienced project engineering team ensured that no onsite integration time would be needed: The complete rack systems and all the remote unit systems were fully built, assembled and tested in advance at our headquarter in Germany. The installation was carried out with our partners TopSide and Pentair. The initial phase of this large pipeline transport project was completed to everyone’s satisfaction, but it is only a start, because three similar projects are in deployment.