Distributed Temperature Sensing (DTS) systems provide temperature information for accurate thermal monitoring, fire detection, and condition assessment by utilizing standard fiber optic cables. These fiber optic systems precisely measure the temperature profile of an asset by interpreting the interaction of light with the glass structure of the optical fiber. Monitoring an asset along the fiber optic cable in real time supplies the information needed to trigger or adjust preventive or corrective actions for assets such as power cables, pipelines, or tunnels.

How DTS Works

Distributed Temperature Sensing (DTS) utilizes standard optical fibers, typically spanning dozens of kilometers, to serve as linear temperature sensors. This approach provides a spatially well-resolved temperature profile along the entire length of the sensor cable, with a resolution down to one meter.

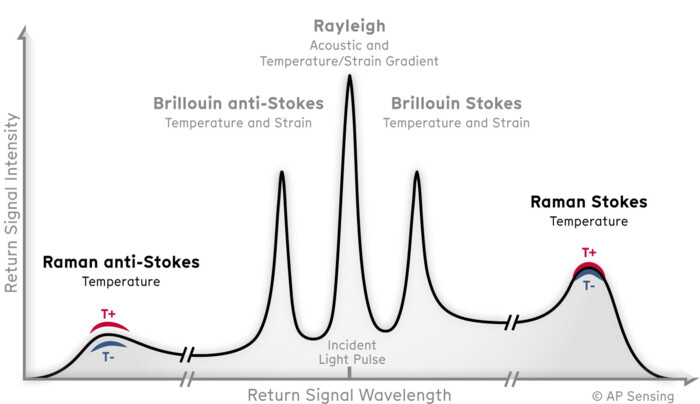

Light Scattering in Fiber Optics, OTDR

DTS technology is based on either Raman or Brillouin optical scattering. A laser pulse is periodically launched into the fiber, from which a small fraction is scattered back due to the interaction of the light with the glass structure. The fraction that is scattered back to the interrogator is continuously analyzed. The position of the temperature reading is derived from the arrival time of the returning light, analogous to radar echo analysis. This method is referred to as Optical Time Domain Reflectometry (OTDR). Technically slightly different, but mathematically equivalent is the Optical Frequency Domain Reflectometry (ODFR). For covering long distance with best signal to noise ratio, the time domain (OTDR) approach shows advantages due to lower shot noise.

Temperature Monitoring Based on Raman Reflectometry

In DTS systems based on Raman scattering, two different Raman components are individually analysed, the Stokes and the anti-Stokes band. The intensity ratio between both signals depends on the local temperature and is used to calculate the temperature along the optical fiber.

AP Sensing uses Raman-OTDR technology with tremendously enhanced performance by the proprietary code correlation (CC) technology. The implementation of CC-OTDR introduces several advantages: It clearly increases the signal-to-noise ratio and thus temperature resolution and distance range, and it facilitates the use of low optical pulse power, effectively mitigating concerns related to potential laser degradation. This makes AP Sensing DTS systems inherently safe in the usage as well as in deployments in EX-rated areas.

Furthermore, a patented single-receiver design provides superior stability of relative amplitudes of both signals and thus temperature. A noteworthy outcome of this approach is the exceptional system reliability achieved.

The Raman system is insensitive to strain on the sensor fiber, allowing undisturbed temperature measurement even in the presence of mechanical tension, a factor that may lead to anomalous temperature readings (e.g. from Rayleigh or Brillouin signals) if not treated in a suitable way.

How Distributed Temperature Sensing (DTS) works using Raman reflectometry:

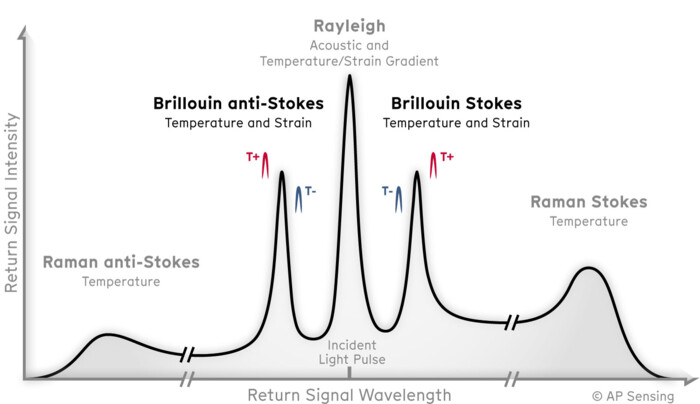

Temperature Monitoring Based on Brillouin Reflectometry

In DTS systems based on Brillouin scattering, the crucial variable measured is the frequency shift of the backscattered Brillouin signal. This frequency, known as the Brillouin frequency shift, responds to alterations induced by the temperature. AP Sensing uses OTDR technology for Brillouin based DTS. Care has to be taken to avoid strain on fibers, e.g. by proper loose tube designs, because the Brillouin-frequency shift is cross-sensitive to strain.

A major advantage of Brillouin based DTS compared to Raman is the stronger back-scattering signal. This enables larger distance ranges, making it especially suitable for monitoring long assets. Additionally, it offers high spatial resolution over long distances and the capability to measure temperature and strain simultaneously.

Benefits & Advantages of Distributed Temperature Sensing

Continuous Temperature Profile Measurement

DTS systems provide continuous thermal information, thus recognizing and precisely localizing any thermal anomalies. With the high coverage of many dozens of kilometers per measurement unit and real-time data, full temperature monitoring makes it possible to pinpoint the exact locations of any hot or cold spot. This feature is crucial for early detection of hotspots, fires or temperature abnormalities indicating faults or other issues.

Additionally, optimized control of cool-down operations is easily enabled with the continuous thermal information provided by the DTS system. This attribute empowers industries to maintain a continuous temperature monitor along the fiber’s length, which aids in anomaly detection, improving operational efficiency, and precise temperature control across a variety of industrial applications.

Maximum Reliability Under Harsh or Explosive Conditions

DTS systems are proven in maximum reliability under harsh and industrial conditions, such as heat, dirt, dust and corrosion. With optical fibers used for sensing, DTS system are non-corrosive and intrinsically safe in explosive atmospheres.

Depending on cable design and used fiber coating, DTS applications cover a wide sensing temperature range from as low as -185 °C (-300 °F) up to +750 °C (+1400 °F) and more. Learn more about fiber optic sensor cables here

Immunity to Electromagnetic Interference

The use of optical, naturally non-conductive fiber makes the sensor immune to electromagnetic interference (EMI or RFI). This immunity stems from the use of light in glass for sensing and signal transmission instead of electrical voltage and current signals that can be disrupted by electromagnetic fields or radio frequency interference. This ensures undisturbed temperature measurements even in environments with high levels of electromagnetic noise.

High Sensitivity and Accuracy

DTS systems provide accurate and reliable temperature measurement for precise analysis. They offer high sensitivity to detect even minor temperature changes, which is also a benefit to predictive maintenance. Thus, they are ideal for applications where small temperature variations are critical, such as in industrial processes and research or in monitoring of changes in the burial depth of a submarine power cable.

Cost-Effectiveness and Low Maintenance Requirements

A DTS system is truly distributed, meaning it responds to heat at any point along the cable equally. The result is a continuous temperature profile across the entire extension of the fiber optic cable, which makes it a unique benefit over conventional sensors for a wide range of applications. Utilizing a single passive fiber optic cable over long distances leads to cost savings in equipment and installation, where usually multiple traditional sensors are required. Low maintenance requirements enhance operational efficiency and long-term cost-effectiveness.

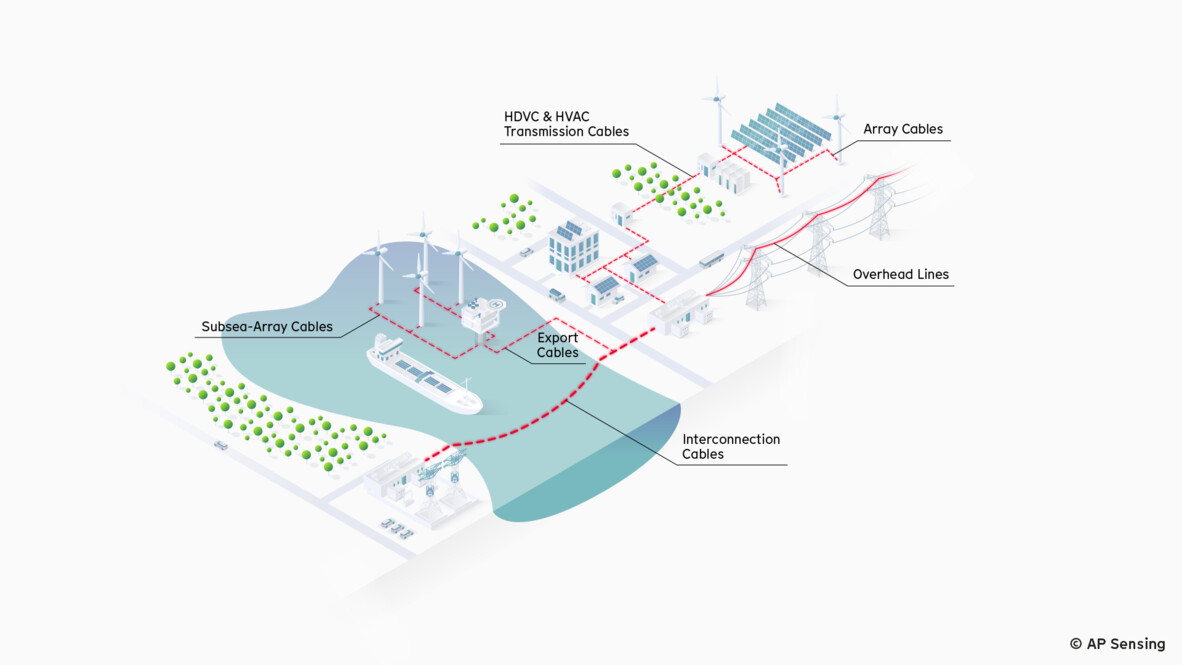

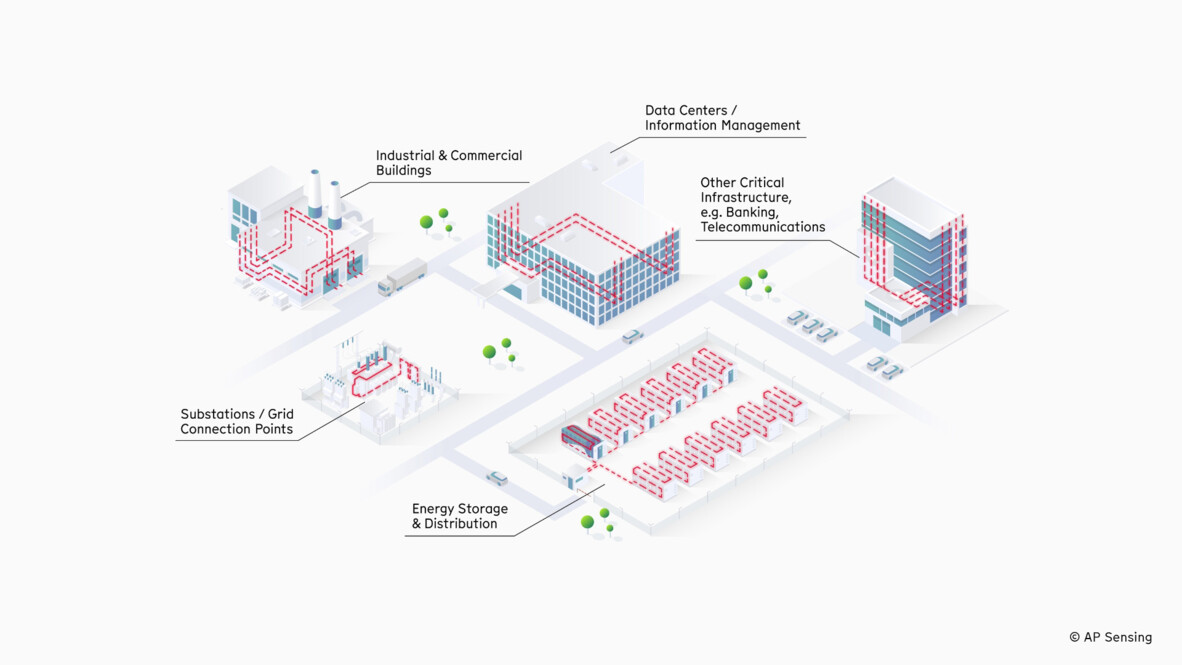

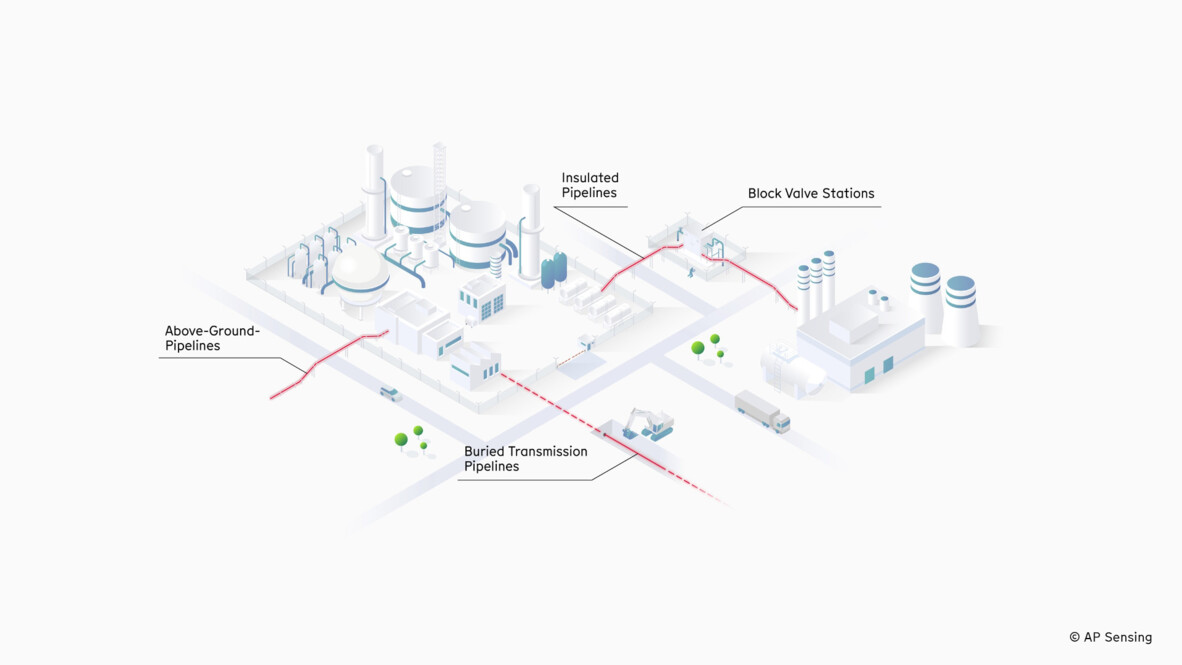

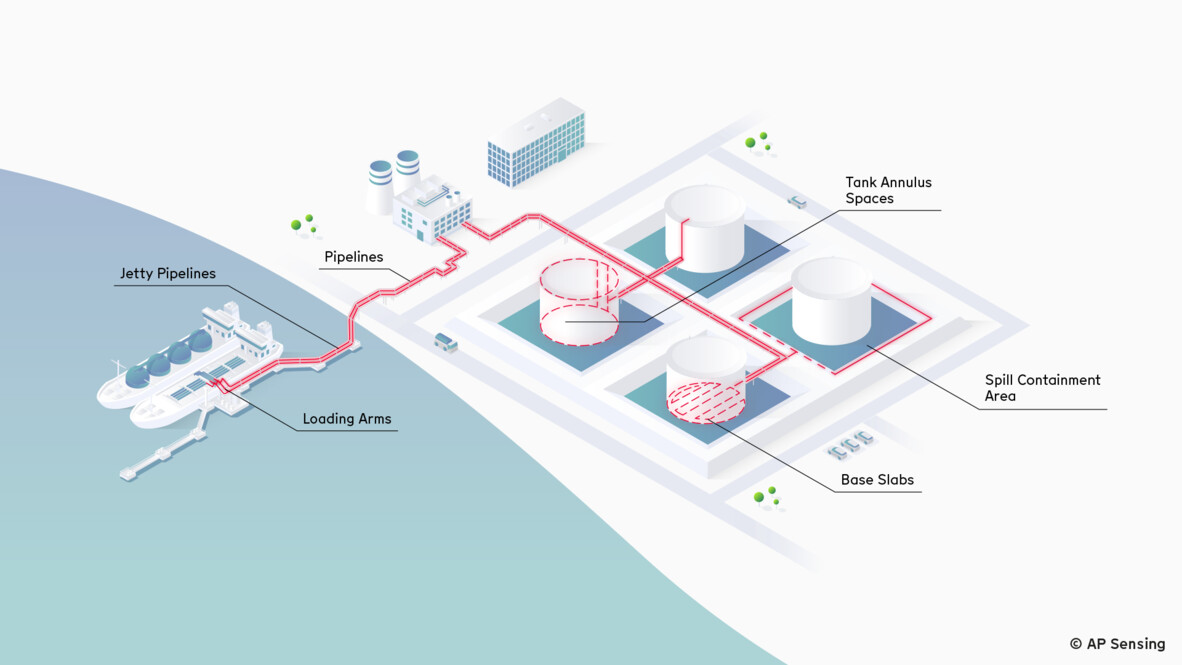

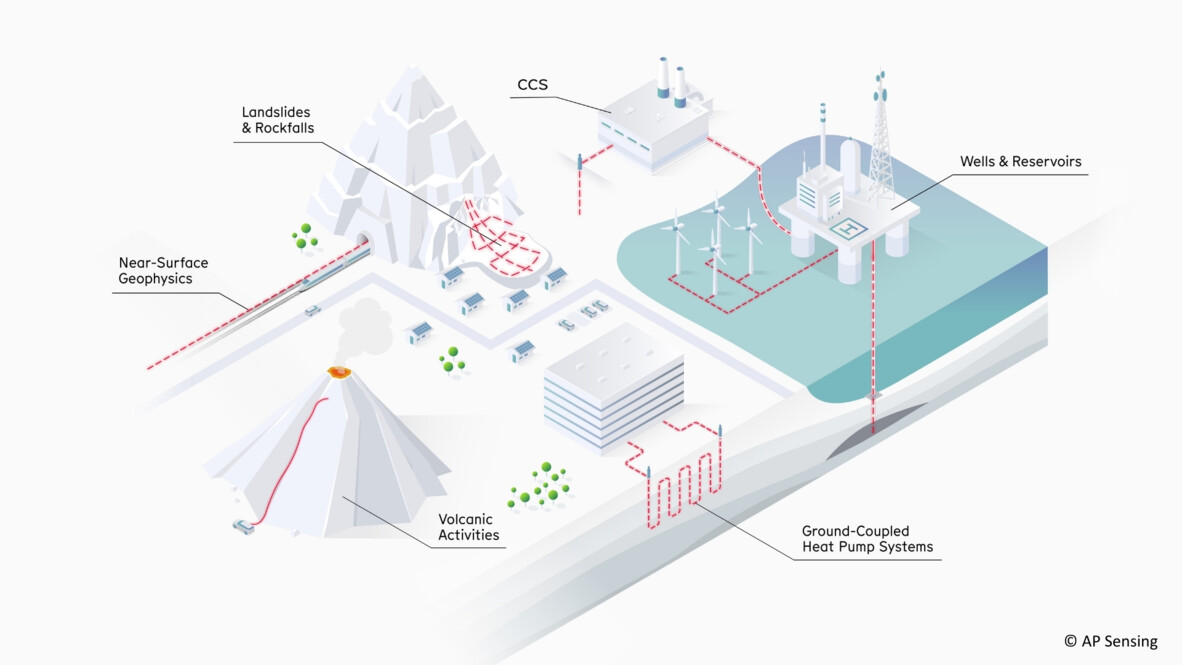

Use Cases of DTS Systems

Distributed Temperature Sensing Systems are indispensable for the most demanding applications. They contribute to enhanced safety, operational capabilities, and temperature surveillance in challenging operational settings.

Thus, DTS systems are employed in a wide array of applications, including temperature detection for power utilities, pipelines, well & reservoir and geothermal monitoring. A big advantage is, that they require low maintenance and easily integrate into existing operational systems.

Some of the key applications of Distributed Temperature Sensing Systems include:

AP Sensing's DTS Systems

DTS N45-Series

AP Sensing covers all market requirements with its systems. Our DTS N45-Series is designed to operate anywhere from the desert to the arctic. With the industry’s most complete set of certifications and stringent type tests, highest product quality and a long product life is guaranteed.

Enhanced DTS (eDTS)

Comprehensive Monitoring Solution in Combination with Distributed Acoustic Sensing

Combining Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) into the enhanced Distributed Temperature Sensing (eDTS) solution offers a robust and comprehensive monitoring solution. This integration addresses both temperature variations and acoustic anomalies, enhancing infrastructure assessment, protection, and optimization. Raman-based DTS provides reliable absolute temperature measurements, while DAS, with its Distributed Temperature Gradient Sensing (DTGS) feature, offers ultra-fast and precise detection of small temperature changes. The combination of these technologies results in improved performance in response time and temperature resolution, offering superior long-distance measurement capabilities compared to DTS alone. eDTS is highly beneficial for measuring accurate temperature profiles where very long distances i.e. > 50 km need to be monitored in applications such as power cable monitoring and oil & gas pipeline leakage detection system.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements.

Key Takeaways

In summary, distributed fiber optic temperature sensors take the way we monitor temperature to a new level. With their distributed and continuous temperature detection, real-time data collection, and large coverage of many dozens of kilometers, they are suitable for widespread application in various industries. Techniques such as Raman optical time domain reflectometry (OTDR) and the implementation of code correlation techniques enable precise temperature measurements over long distances, significantly enhancing signal-to-noise ratio, temperature resolution, and distance range.

Whether it’s power cable infrastructure monitoring, pipeline leak detection or oil and gas exploration, fiber optic temperature sensors are set to remain an integral part of temperature monitoring systems.

Frequently Asked Questions (FAQs)

This FAQ section shares practical, vendor-neutral insights to support engineers, operators, and decision-makers working with DFOS.

It is supported by Dr. Gregor Cedilnik, Principal Research Scientist at AP Sensing and a leading expert in distributed fiber optic sensing technologies. With decades of experience in fiber optics, photonics, and DFOS system design, he has authored numerous technical publications and patents and helped shape several of AP Sensing’s core platforms.

What is Distributed Temperature Sensing (DTS)?

DTS uses an optical fiber as a continuous temperature sensor. A light pulse is sent through the fiber, and the backscattered signal is analyzed to generate a temperature profile along the entire length, often spanning many kilometers. This enables precise detection and localization of temperature changes, including hot and cold spots.

How does Raman-based DTS work?

Raman-based DTS measures the ratio between two light components, Stokes and anti-Stokes, which varies in a defined way with temperature. Using OTDR (Optical Time Domain Reflectometry), the system converts the time of flight into distance along the fiber. This results in a temperature profile mapped over the entire fiber length.

How does Brillouin-based DTS differ?

Brillouin DTS derives temperature information from the frequency shift and/or power of the backscattered Brillouin signal.

Since the Brillouin signal is sensitive to both temperature and strain, the system design, cable characteristics, and signal processing techniques are used to separate or compensate for these effects. Brillouin methods like BOTDR (Brillouin optical time domain reflectometry) are well-suited for long reach measurements and can support combined temperature-and-strain sensing (DTSS).

Raman vs. Brillouin: when to choose which?

- Raman DTS: robust absolute temperature measurement over long distances with straightforward calibration.

- Brillouin DTS: advantageous for very long reaches or where temperature and strain interactions must be considered or co-measured.

The choice is based on the required reach, spatial resolution, update rate, and whether strain needs to be measured or decoupled.

What distances and spatial resolution are typical for DTS?

The choice of fiber depends on the sensing principle and application.

Multimode fiber (MMF) is typically used in Raman-based DTS systems.

In contrast, Brillouin-based DTS systems generally use singlemode fiber (SMF).

For installations with tight routing, bend-insensitive variants can help maintain signal quality.

In many cases, existing fibers can be reused for Distributed Temperature Sensing (DTS).

Always select the appropriate fiber and cable construction based on sensing range, environmental conditions, and installation requirements.

What are typical DTS applications?

Distributed Temperature Sensing (DTS) is commonly used for monitoring power cables and substations, pipelines and industrial processes, storage tanks, transportation tunnels and bridges, as well as in geotechnical and hydrological projects. These applications benefit from continuous thermal profiling, early anomaly detection, and accurate event localization.

How fast are DTS measurements updated?

Raman-based DTS typically provides temperature updates every few seconds to several minutes. For shorter fiber links and lower averaging settings, refresh times of approximately 1 to 10 seconds are possible. For longer distances or finer spatial resolution, update intervals of 10 to 60 seconds or more are often used to improve signal-to-noise ratio (SNR).

Brillouin-based DTS generally updates within a range of seconds to minutes, depending on the specific BOTDR scheme, sensing range, and whether temperature and strain are measured simultaneously. Very long distances or high-resolution measurements may require longer averaging times, typically between 10 and 120 seconds.

Performance trade-offs apply: faster update rates reduce averaging and may increase noise, while longer averaging improves measurement stability but increases latency.

Can existing telecom fibers be used?

Often yes - if the fiber route and attenuation are suitable and access to the fiber is possible. Reusing dark fiber (i.e. not used for telecommunication) can lower deployment cost; connectors/splices, thermal coupling to the asset, and environmental ratings should be validated to ensure accuracy and stability.

What drives accuracy and measurement stability of a DTS?

The accuracy of a Distributed Temperature Sensing (DTS) system is strongly influenced by installation quality and system configuration.

For Raman-based DTS, key influencing factors include:

- the signal-to-noise ratio (SNR), impacted by optical attenuation, splice quality, and connector integrity

- proper calibration of the anti-Stokes/Stokes ratio, typically using reference sections or known ambient temperature points

- the choice between single-ended or double-ended fiber coupling

- the thermal coupling of the sensor cable to the monitored asset (e.g., mounting method, attachment technique, cable sheath type)

- system settings such as spatial resolution and measurement integration time

- thorough commissioning measurements (baseline) and periodic verification to ensure long-term performance

For Brillouin-based DTS, the above factors also apply. In addition, attention should be paid to:

- effective separation of temperature and strain effects, using reference fibers, mechanically decoupled sections, or strain-isolated routing

- avoiding unintended mechanical stress during cable installation

- clear definition and segmentation of measurement zones to support reliable temperature and strain data interpretation

How is a DTS system integrated and visualized?

DTS data are typically ingested into monitoring software for real-time alarms, trend analytics, and map-based visualization. Common outputs include geo-located events, thresholds, and interfaces (e.g., APIs or industrial protocols) for SCADA/EMS/DCS integration.

In safety-critical applications, such as fire detection, relay outputs enable direct alarm forwarding to a fire alarm control panel (FACP) or other safety systems.

Can DTS be combined with other distributed sensing?

Yes. Combining different Distributed Fiber Optic Sensing (DFOS) technologies can be beneficial in many applications to gain a more comprehensive understanding of asset conditions. In the simplest case, DTS and DAS (Distributed Acoustic Sensing) are operated in parallel on separate fibers within the same cable.

In some deployments, Brillouin-based DTS can operate alongside DAS (Distributed Acoustic Sensing) on the same single-mode fiber (with appropriate wavelength / architecture planning), providing complementary temperature and acoustic / vibration insights for richer diagnostics.