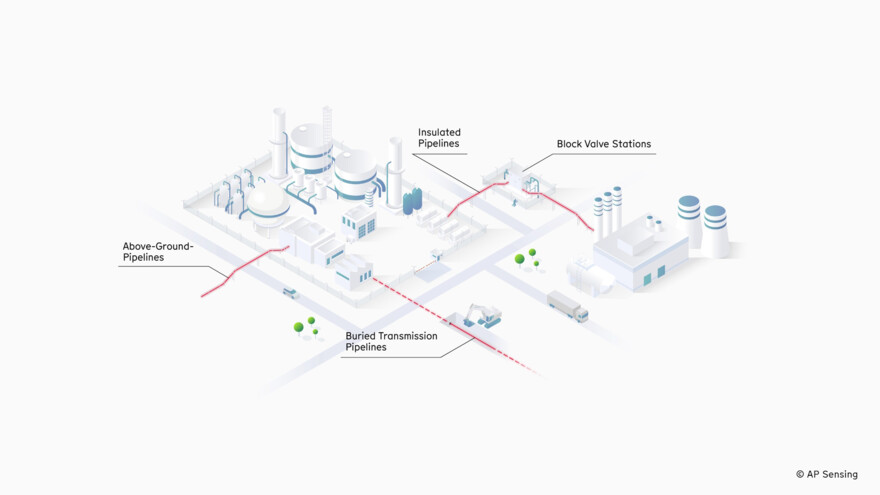

Distributed Fiber Optic Sensing (DFOS) provides the capability to monitor your entire pipeline infrastructure 24/7. By utilizing a fiber optical cable as a sensor, this technology ensures early detection and accurate localization of events like pipeline leaks or external threats. Distributed Acoustic Sensing (DAS) technologies, Distributed Temperature Sensing (DTS) and Distributed Temperature & Strain Sensing (DTSS) provide pipeline operators with a monitoring solution to reduce downtimes, enhance safety, achieve regulatory compliance, and protect valuable assets. AP Sensing's pipeline monitoring solution encompasses the detection and location of leaks, real-time PIG-tracking, pipeline intrusion detection (PIDS) and third party intrusion (TPI). Additionally, our solution extends to monitoring block valve stations, refineries, processing plants, and storage facilities.

Understanding Pipeline Threats

Pipelines are subject to sophisticated pipeline theft actions, malicious interference or unauthorized digging on the right of way, especially in remote locations or farmland. These threats, and others like landslides, can be detected fast, utilizing a standard fiber optic cable as a sensor along the pipeline. This monitoring solution provides complete, continuous monitoring coverage along the entire pipeline. AP Sensing's systems detect and accurately locate changes in temperature, noise, vibration, and strain around a pipeline.

Flow assurance monitoring can be achieved by detecting hot/cold spots, as well as by the acoustic signals of flow constrictions or liquid accumulations. Our solution detects even pinhole leaks and delivers alarms quickly while locating the event within a few meters. Distributed Acoustic Sensing, Distributed Temperature Sensing and Distributed Temperature & Strain Sensing can be used on their own or together depending on the specific characteristics of the pipeline being considered.

AP Sensing's Monitoring Solutions

AP Sensing is your trusted partner for pipeline monitoring. We understand your challenges and work to deliver the optimal DFOS solution for your pipeline project. Our comprehensive offering meets your monitoring needs and safeguards your valuable assets. AP Sensing provides a complete package, including:

- System design built around proven components

- Project management and engineering

- Installation and commissioning plus through-life support

Our international project teams consist of multidisciplinary, highly skilled and passionate engineers and field support who combine their experience and expertise to deliver on our commitments.

Different types of pipelines have different operational requirements and conditions. With AP Sensing’s solution various types of pipelines can be monitored to ensure efficient and reliable delivery, including:

- Crude Oil and refined products

- LNG, LPG

- Gas

- Water and sewage

- Slurry and other mining pipelines

- Cryogenic fluids

- Various multiphase regimes

Event Detection

AP Sensing's solution detects and locates the following events:

- Pipeline leaks

- Pipeline rupture and ignition detection

- Third party intrusion (TPI), intrusion detection systems (IDS)

- Real-time scraper/PIG tracking

- Liquid accumulations

- Slugs

- Process control/flow assurance in heated pipelines

- Flow constrictions caused by waxing or hydrate formation

Technologies Used in Pipeline Monitoring

AP Sensing's pipeline monitoring solution is an integrated fusion of Distributed Fiber Optic Sensing technology, hardware and detection algorithms, plus intuitive interface software. Our Distributed Acoustic Sensing (DAS), Distributed Temperature Sensing (DTS) and Distributed Temperature & Strain Sensing (DTSS) provide monitoring capabilities over hundreds of kilometers, all while minimizing false alarms and maximizing probability of detection. Our DAS, DTS, and DSS technologies can be used separately or combined; each delivers unique benefits for pipeline leak detection and continuous monitoring.

Distributed Acoustic Sensing (DAS)

AP Sensing's DAS system provides TPI monitoring, detects negative pressure wave signatures, and detects leaks using multiple methods including Distributed Temperature Gradient Sensing (DTGS) technology. Our 2P Squared DAS is an enhanced, quantitative DAS (true phase-based) system that enables quantitative measurement of acoustic signals and strain amplitude over extended distances. This unique technology provides significant improvements to the signal-to-noise ratio (SNR), as well as a longer sensing range.

Distributed Temperature Sensing (DTS)

DTS detects pipeline leaks by recognizing and precisely localizing any cold or hot spot. It identifies thermal anomalies, such as the cooling effect of an escaping gas, or assists in the management of active heating processes, such as in a sulfur pipeline. Temperature monitoring of pipe walls is used to assist heat tracing systems to maintain optimal performance and safety.

Distributed Temperature & Strain Sensing (DTSS)

Distributed Temperature & Strain Sensing (DTSS) in pipeline applications allows engineers to monitor the temperature and to detect and locate significant geohazards like ground shifts and rock fall events, enabling prompt response to potential threats and preventing damage or product loss. By recording all activities around a pipeline before and after disturbances, like earthquakes, DTSS helps assess damage and maintain asset integrity.

Our Innovative Software Solutions

SmartVision Software

AP Sensing's SmartVision Software Suite shows the condition of your pipeline at a glance, controlled by an easy-to-use graphical user interface (GUI). It seamlessly integrates many technologies, such as DTS, DTSS, DAS, CCTV and other sensors into a single platform. Pipeline layouts are mapped and color-coded to show the measured pipeline temperatures, as well as instantaneous changes in acoustic energy. Alarms are shown on the screen in an emergency situation, and the operator is directly informed about the location of the critical incident. Temperature graphics and hotspot tables are readily available, and sections of the cable route can be individually defined for flexible alarm levels and types.

AP Sensing’s API 1130 Acoustic CPM (Computational Pipeline Monitoring) LDS software uses the input from DAS to analyze the acoustic signal from a pipeline leak. Our leak detection software complies with the recommendations of API 1130 CPM for CPM Acoustic leak detection method. Conditions such as multiphase, which cause many API 1130 CPM methods great difficulty, can indeed generate an additional acoustic signal and be easily detected by AP Sensing's API 1130 Acoustic CPM.

Alarm Management

Basic thresholds for maximum temperature, temperature gradients, or differences to average temperatures enable reliable protection of pipelines. These parameters can be customized per detection zone depending on environmental conditions and expected critical thresholds, ensuring a precise fit for each pipeline.

Machine Learning Transient Alarm (MLTA)

AP Sensing’s MLTA technology detects hidden pipeline abnormalities by analyzing temperature traces from DTS systems. Our advanced machine learning algorithm isolates thermal transients, detecting even the smallest cold or hot spots. This ensures fast, reliable alarms for enhanced pipeline safety and efficiency.

Advantages of AP Sensing's Pipeline Monitoring System

Compliance

Complying with regulations is a key consideration for pipeline monitoring systems. The combination of AP Sensing's DTS, DTSS and DAS systems provides optimal protection for both onshore and offshore pipelines, ensuring pipeline integrity in a variety of operational conditions.

AP Sensing's Distributed Temperature Sensing and Distributed Acoustic Sensing technologies are both recognized as an internal and external pipeline leak detection method according to API 1175 - Pipeline Leak Detection Program Management. External Pipeline Leak Detection Methods are an important part of the API 1175 Pipeline Leak Detection recommended best practices.

Shell DEP (Design Engineering Practice) 31.40.00 – Pipeline Engineering also recommends that a combination of internal and external leak detection methods is considered to improve the leak size detection threshold, reducing the time to detect a leak and/or defining the leak location accurately.

AP Sensing’s DAS system is also compliant to German TFRL and Saudi Aramco SAES-Z-003 standards. With a wide range of certifications and type tests including ATEX and SIL, our DTS system provides a durable and robust field solution with industry leading performance and reliability.

Continuous, Real-Time Monitoring

Fiber optic sensing systems provide continuous monitoring along the entire length of the pipeline, allowing real-time and early detection of potential issues, helping to prevent accidents, minimize downtime, and react proactively.

High Sensitivity & Accuracy

Fiber optic sensors offer high sensitivity and accuracy, allowing for precise measurement over long distances. This enables reliable detection of small changes that may indicate leaks, damages, or other pipeline abnormalities.

Long Range Coverage

Fiber optic sensing cables can monitor long distances over 150 km without the need for additional sensors or monitoring points, reducing installation and maintenance costs. This long-range coverage allows for comprehensive monitoring of extensive pipeline networks, including remote or inaccessible areas.

Non-Intrusive and Virtually No Maintenance

Fiber optic sensing systems do not interfere with pipeline operations and have minimal maintenance requirements once installed, reducing operational costs and downtime associated with maintenance activities.

Comparable Monitoring Techologies

Pressure and Flow Based Pipeline Leak Detection

The main advantages of fiber optic sensing-based pipeline leak detection are:

- Higher sensitivity

- Accurate localization of leaks within 1 to 5 m

One of the main advantages is the fact that its performance is not affected by the presence of hydraulic transient. While pressure sensors offer high accuracy and reliability, they provide point measurements and require multiple sensors for comprehensive monitoring of long pipelines. While flow meters provide accurate measurement of the flow rate of fluids within pipelines, they usually require installation at specific points along the pipeline, as well as periodic calibration.

Point Acoustic Sensors

Acoustic sensors detect vibrations generated by leaks at above ground installations. While offering real-time detection capabilities, acoustic sensors have limitations in terms of range and sensitivity compared to distributed fiber optic sensing.

Satellite and Remote Sensing Technologies

Satellite and remote sensing technologies monitor pipelines from a distance using satellite imagery, aerial surveys, or ground-based sensors. These technologies can provide valuable insights into environmental conditions surrounding the pipeline, but offer limitations in terms of sensitivity, availability and accuracy.

Challenges in Leak Detection

There are numerous challenges associated with pipeline leak detection including detection sensitivity, false alarms, precise localization of leaks, changes in pipeline hydraulic conditions, and environmental factors. AP Sensing's leak detection method mitigates the challenges of pipeline leak detection by combining advanced sensor technologies, multi-parameter monitoring, precise localization, continuous monitoring, adaptive algorithms, and robust design to provide accurate and reliable detection of leaks in pipelines with a low false alarm rate.

Advanced Methods of Pipeline Leak Detection

As the field evolves, advanced techniques using machine learning algorithms and fiber optic sensing cable are improving the accuracy and efficiency of pipeline leak detection. These solutions are becoming key components in pipeline leak detection systems (LDS), significantly enhancing efficiency compared to traditional methods. DFOS-based pipeline leak detection and location software (DFOS-PLDS) is recognized by the leading pipeline consultancy companies as a leading-edge pipeline leak detection solution suitable for various pipeline fluids and conditions.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.