The global push for renewable energy, rising demand for electricity, and the need to cut emissions are transforming our power grids. To keep pace, reliable cable systems are critical, and so is knowing exactly the asset condition.

New Insights from CIGRE: Uncover the Latest Cable Failure Statistics

CIGRE , the leading global network for power system experts, recently published the latest failure statistics for insulated high-voltage cables covering the years 2012 to 2021. These reports are essential for understanding how our grid infrastructure is performing and where risks lie.

One thing is clear: Extruded AC land cables, especially those made with XLPE insulation, dominate today’s grids. Since 2005, they account for 98 percent of all AC cables installed above 100 kV, totaling nearly 29,000 circuit-kilometers are reported.

But even these reliable cables are not immune to failures.

On average, AC land cables above 100 kV experience one failure every 561 circuit-kilometers per year, leading to roughly 38 days of downtime. That is why monitoring is important.

See It Coming: How Our Technology Detects Failures Early

AP Sensing’s Distributed Fiber Optic Sensing (DFOS ) and Fiber-based Current Monitoring (FbCM ) solutions provide up to 85 percent coverage of components within these cable systems. Our technologies detect faults, pinpoint their location, and help operators react quickly before a minor issue becomes a major outage.

What can we detect?

- External impacts, such as construction damage

- Internal failures, including problems within the conductor, insulation, or cable sheath

- Thermal hotspots that indicate developing faults

By monitoring sheath currents, AP Sensing’s FbCM solution offers early insights into component health and provides valuable trend data over time. For critical spots like joints, integrating fibers directly inside allows for precise thermal monitoring that no other external point sensor can achieve.

Failure Causes in Land Cables

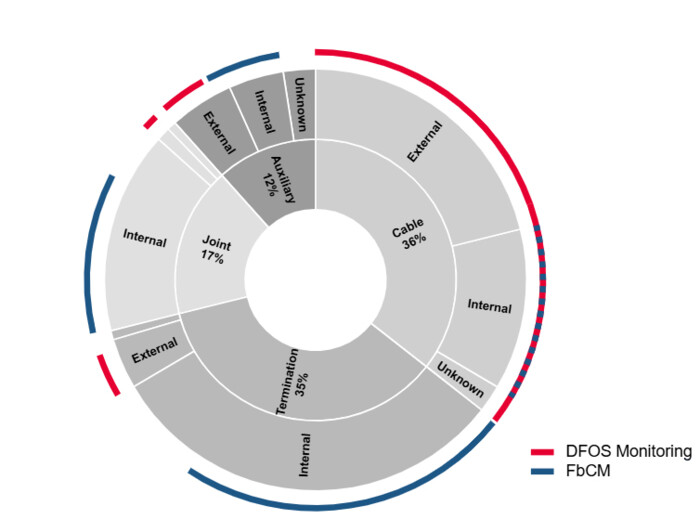

The graphic below illustrates which components of a land cable system are most affected by failures and shows how AP Sensing’s monitoring solutions help detect and localize them:

The inner circle shows the different parts of a cable system: The cable itself, joints, terminations, and auxiliary equipment.

The outer segments indicate the causes of failure: Internal faults, external damage, or unknown reasons.

The colored lines reveal where our solutions provide coverage:

- Distributed Fiber Optic Sensing (DFOS, red) detects external threats and severe internal faults along the entire cable length and can precisely localize failures, even directly at the cable itself.

- Fiber-based Current Monitoring (FbCM, blue) measures sheath currents, which are a key indicator of internal health, especially at joints and terminations. This often provides early warnings before severe failures occur.

Submarine Cables: Monitoring Where Access is a Challenge

Underwater cables present unique challenges, and failures are costly. Repairing a damaged submarine cable means an average downtime of 99 days and expensive repair-vessel operations.

Despite the lower failure rate (around one failure per 3,431 kilometers per year), the economic impact is significant.

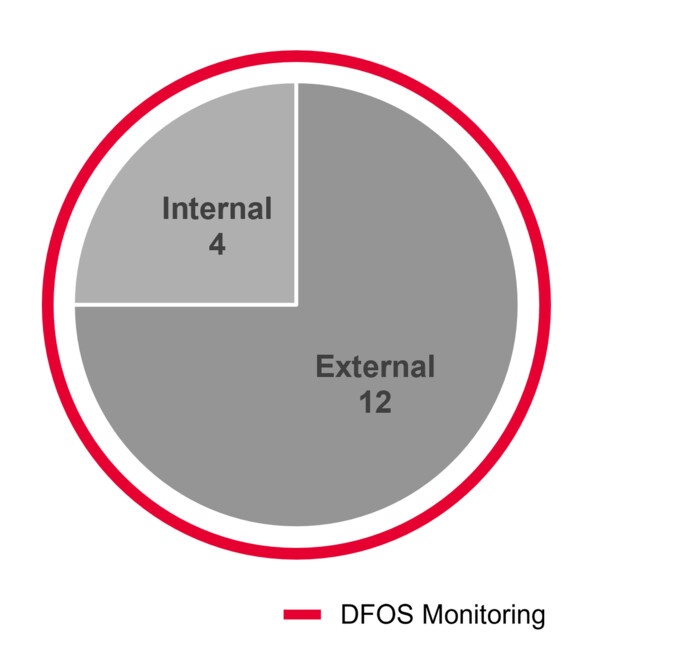

This pie chart summarizes the 16 total failures observed during the study period:

4 failures were classified as internal, meaning they originated within the cable itself (e.g., insulation, conductor, or sheath issues).

12 failures were classified as external, resulting from outside influences like anchors, trawling, or environmental impacts.

The red circle emphasizes that AP Sensing’s Distributed Fiber Optic Sensing technology is capable of detecting both internal and external failures in this system

With DFOS, operators gain:

- Early detection of external threats such as ship anchors or fishing activities

- Depth of Burial (DoBS ) monitoring to reduce external damage risks

- Fault localization over long distances without the need for remote equipment

The result is reliable, real-time insights that protect critical infrastructure both above ground and beneath the sea.

Overcoming the Blind Spots of Conventional Point Sensor Systems

Power cables, especially in demanding environments, need more than isolated snapshots. Traditional point sensors, typically installed at specific locations like terminations or joints, only monitor small sections of the system. They provide limited data and leave significant parts of the cable unobserved.

AP Sensing’s distributed monitoring solutions offer a clear advantage:

DFOS and FbCM technologies provide continuous, system-wide coverage. They deliver real-time visibility along the entire cable system, offering early detection of both external threats and internal degradation. Unlike other point sensors, our solutions do not require remote equipment along the route, which simplifies installation and enhances long-term reliability.

Key Takeaways

- DFOS provides superior detection and localization for power cable monitoring with no extra equipment required along the cable route. It delivers full coverage and outperforms point sensors with continuous system visibility and fast fault localization.

- FbCM enhances monitoring by measuring sheath currents, offering early warnings of internal failures.